Bed Ash Cooler Working Principle

BASIC DESIGN OF CIRCULATING FLUIDIZED BED BOILER 8 FEBRUARY 2012 Pichai Chaibamrung Asset Optimization EngineerReliability Maintenance Asset Optimization Section Energy Division Thai Kraft Paper Industry CoLtd.

Bed ash cooler working principle. The resultant fast and intimate mixing of gas and solids promotes rapid heat transfer and chemical reactions within. Working Principle of Fluid Bed Drying System. Fluidization causes the transformation of the state of solid.

The fuel is transported from mines via trains to the fuel storage facility in a power plant. Working Components of Thermal Power Plant. This lifts the bed material and the coal particles and keeps it in suspension.

A bed of solid particles is said to be fluidized when the pressurized fluid liquid or gas is passed through the medium and causes the solid particles to behave like a fluid under certain conditions. With over 280 installations across the world the boiler offers benefits like fuel flexibility high efficiency low emissions and. Types Combustion in boilers Performances evaluation Analysis of losses Feed water treatment Blow down Energy conservation opportunities.

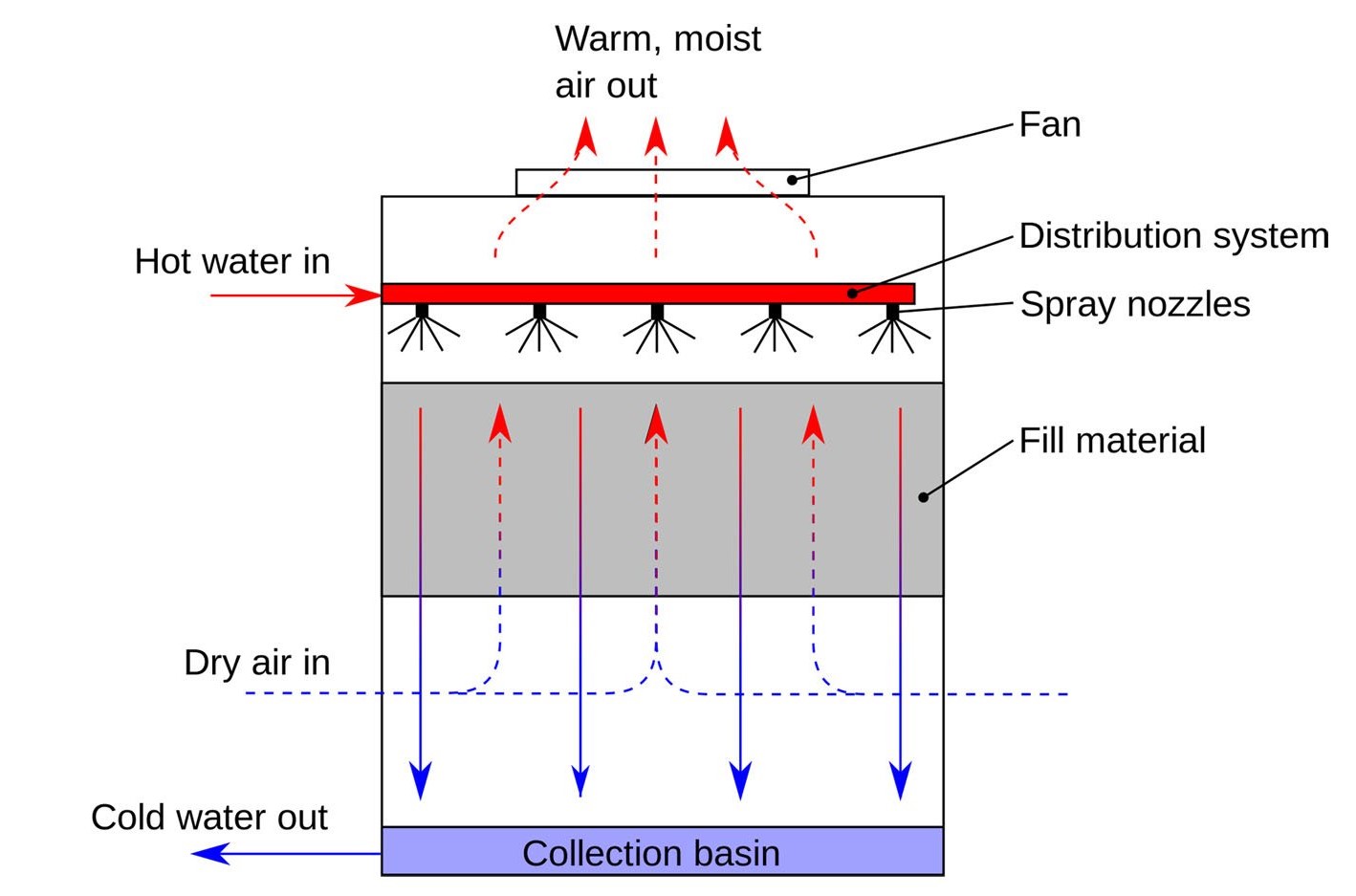

If the Wet Bulb Depression is 30ºF and the actual temperature drop measured across the cooling media is 27ºF as in the above example the cooling efficiency is 90. Ash spouts in the furnace remove the ash from the bottom of the furnace. Fluid bed technology is used for cooling heating and drying of bulk solids materials.

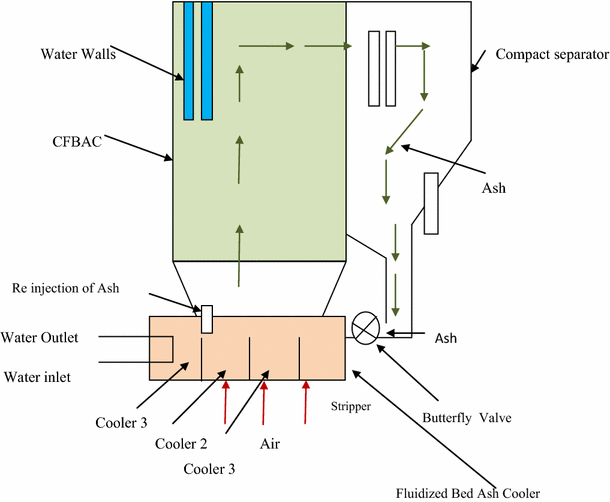

Bottom ash is removed from the furnace via two ash control valves ACV and then is in-. Fluid bed heat exchange takes place by passing a gas most commonly air through a perforated distributor plate which then flows through a layer bed of solids. In its most basic form fuel particles are suspended in a hot bubbling fluidity bed of ash and other particulate materials through which jets of air are blown to provide the oxygen required for combustion or gasification.

At the bottom of the boiler furnace there is a bed of inert material. The fuel transported to the plant is generally bigger in particle size and before it is fed to the boiler furnace it is. Continue fluidizing the bed to cool down the system at 2 Cmin by reducing SUB firing rate 13.