Batch Fluidized Bed Dryer

Fluidized bed dryer also called fluid bed dryer is a kind of equipment used extensively in the pharmaceutical industries to reduce the moisture content of pharmaceutical powder and granules.

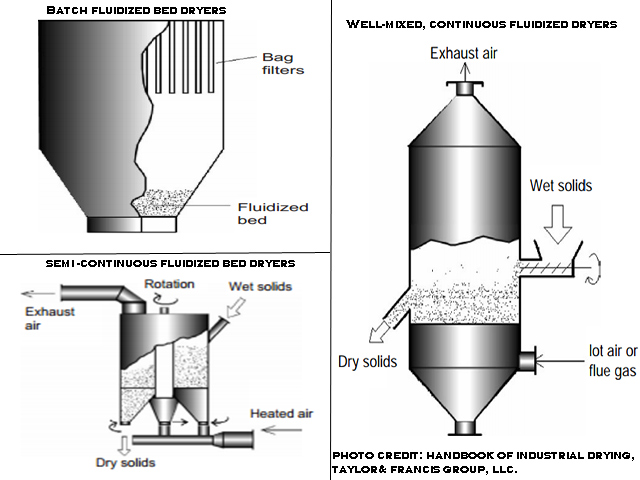

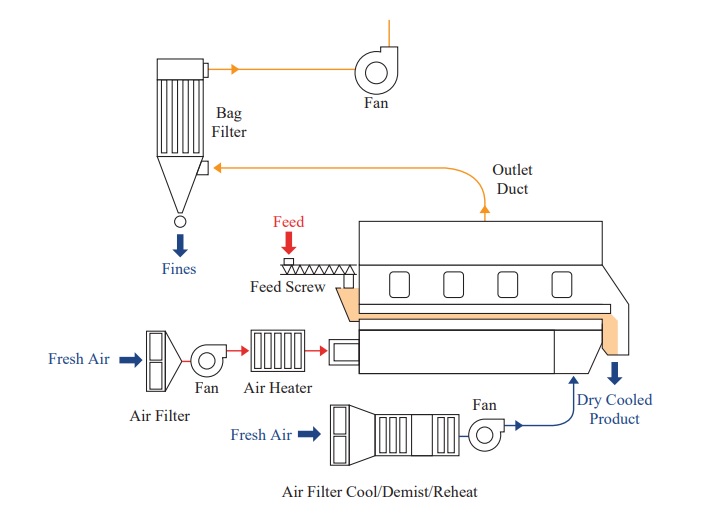

Batch fluidized bed dryer. Feeding drying and discharging processes are repeated in a batch process. GFG food lab use batch fluid fluidized bed dryer drying machine for sale. In batch fluidized bed dryers the drying process is carried out step by step according to a product-specific recipe meaning drying at different supply air temperatures and air flow rates.

It may be advantageous to preform other materials such as a dewatered filter cake into granules solely to employ fluidized bed drying. In batch type fluidized bed dryers the machine uses two mechanisms to discharge materials. Fluidized bed dryer loading.

It enhances the products properties Ie. The present work develops a mathematical model for batch fluidized-bed drying. 43C A Kerosene burner 20 l keroseneh B Rice hull furnace 3-4 kg rice hullh Fan Axial flow fan 2200 rpm.

Here the FDB depends on the direction type perforated plate. In the fluidized bed dryer the particles are particularly suspended in a mobile gas stream Hot Air the air serves as a boiling liquid in the sense that the particles are first lifted upward and then they fall back. Bakers yeast cake was extruded into the dryer through a perforated.

Batch mode fluidized bed dryers such as the one shown below are widely used in the pharmaceutical industry due to the small production volume requirements and vital quality assurance. Hot gas is supplied from the bottom of B-FBD through the perforated plate to fluidize and dry the powder materials. Order Contact Supplier Transaction Level Add to Compare.

The drying air flow rate is also usually fixed. Fluidized bed dryer dryers dont have lots of moving parts and require little maintenance. Firstly the experimental works by using lab-scale batch fluid bed dryer was conducted to determine the drying curve of.