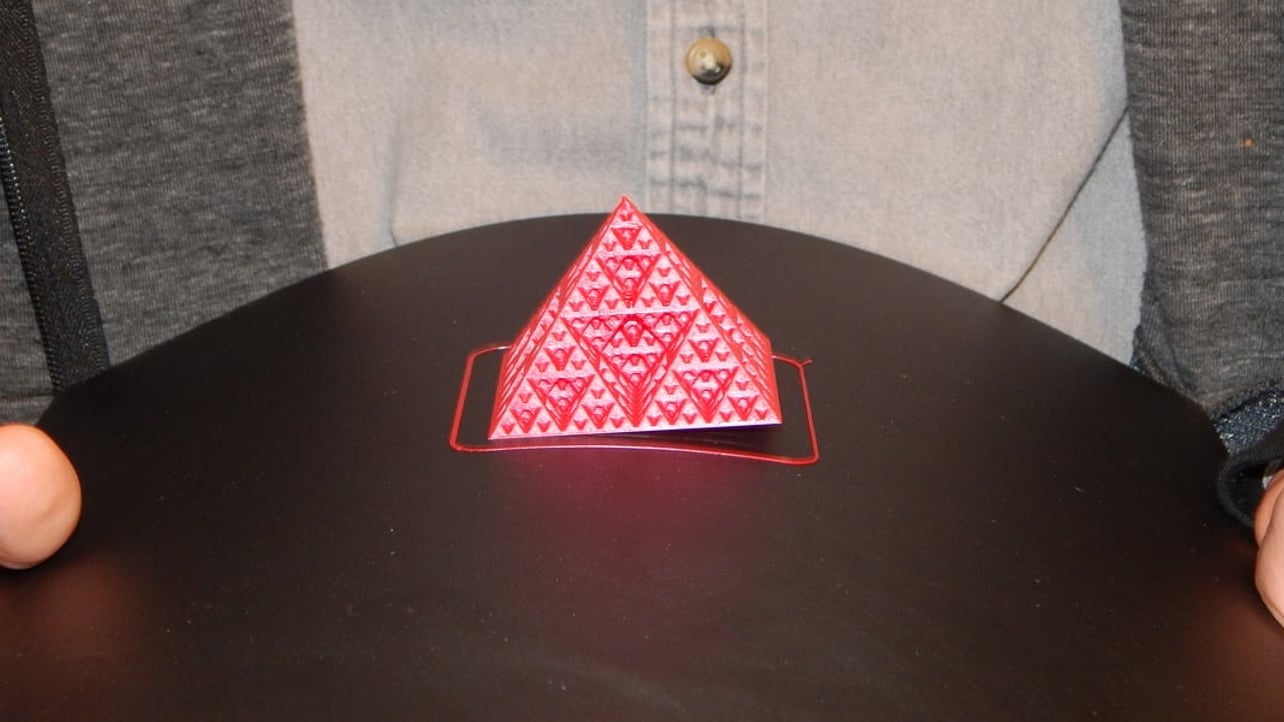

Buildtak Heated Bed

Uses Folding Fire box.

Buildtak heated bed. If you dont do this the print wont stick to the Buildtak and will make a mess. Works with PLA ABS HIPS PET Brick Wood. Full be ovality 175mm BuildTak able Print listed spool.

Theres no need to alter any of your bed parameters when printing with BuildTak ABS will still print best at 100 to 110 C while PLA should print well even without a heated bed. Postby VickyRaise3D Sat May 06 2017 507 pm. Ideal Jacobs the manufacturer of BuildTak says the surface has a 250 hour working lifetime on non-heating beds and 50 to 10 hours with heated beds.

Glass is a fickle friend. Heated print beds are not a problem BuildTak is composed of high quality raw materials and is designed to withstand the high temperatures of a typical FFF 3D printer ie. Then use a small fan to quickly cool the platform or at least quicker than room temperature.

A have predictable your including our on stretchers vacuum provides Temp. Despite its powerful adhesive capabilities Buildtak is still not going to provide enough adhesion to negate the use of a heated print bed. Some people just clean their print bed and adhesion works great.

Ive heard some really advanced materials do great with BuildTak although it can be quite premium. Used it initially on my Anet A6. Developed by tinkerers for tinkerers BuildTak sheets are the ideal 3D printing surface.

Why a heated bed is necessary for 3D printing. BuildTak is a great surface even on unheated beds but prints can stick too well. Heated print beds are not a problem BuildTak is composed of high quality raw materials and is designed to withstand the high temperatures of a typical FFF 3D printer ie.