Bubbling And Circulating Fluidized Bed

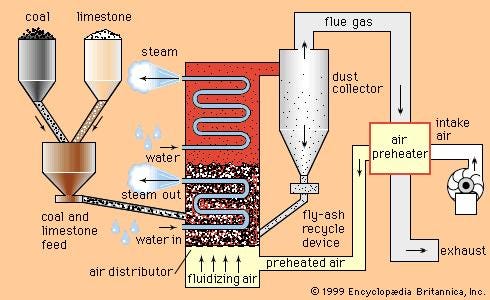

In this chapter fundamental concepts of fluidized beds including the definition and characteristics of fluidized bed basic CFB boiler structure several types of CFB boilers and notable characteristics of CFB boilers are introduced.

Bubbling and circulating fluidized bed. Three-dimensional flow structures of dilute suspensions in the freeboard of a bubbling fluidized bed as well as in a circulating fluidized bed of 200 mm internal diameter roughly a 1 25-scale model of a commercial boiler were observed by the laser sheet technique. This work compares the dynamic behaviour of the flue gas side of large-scale bubbling and circulating fluidized bed BFB and CFB respectively boilers. In current applications circulating bed reactors encompass primarily Groups A and B.

In a bubbling fluidized bed. Investigating different hydrodynamic models show that combining two-phase-structure model with reaction kinetics for bubbling fluidized bed gasifiers improves the accuracy of the kinetic-only model. Fluidized Bed Combustors for Biomass Boilers Boiler engineers can choose between two main types of fluidized-bed boilersbubbling fluidized bed BFB and circulating fluidized bed CFB.

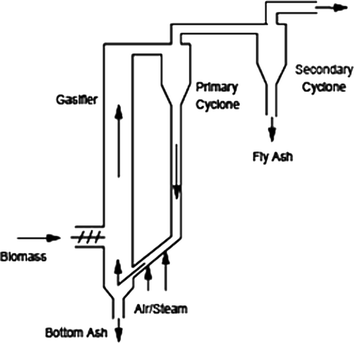

The results from biomass gasification in a pilot-scale 6 m tall 02 m internal diameter air-blown circulating fluidized bed gasifier was tested and compared with bubbling fluidized bed gasifier. For this a dynamic model is developed and presented. In CFBC a distinction between the bed and the.

From the table it is clear that the CFBs have slightly better characteristics. Circulating beds are quite distinct from conventional ie. The second type of combustion chamber has a fast bed at the upper part and a bubbling bed at the lower part which is called circulating fluidization.

An internally circulating fluidized bed ICFB is a type of fluidized bed with a centrally located draft tube or a plate that divides the bed into two or more sections and thus promotes solid circulation within a single vessel. The circulating fluidized bed boiler CFB boiler is the second-generation fluidized bed boiler the updated version of the bubbling fluidized bed boiler BFB boiler. The performance of sawdust gasification in a 03 m 03 m bubbling fluidized bed gasifier BFBG is compared to that in the ψ 04 m circulating fluidized bed gasifier CFBG.

The bubbling fluidized bed had a dense zone and bed material was. Bubbling and slugging fluidized beds whereas they overlap substantially with transport reactors. A more detailed comparison between industrial-size bubbling and circulating fluidized beds is given in Table 8.