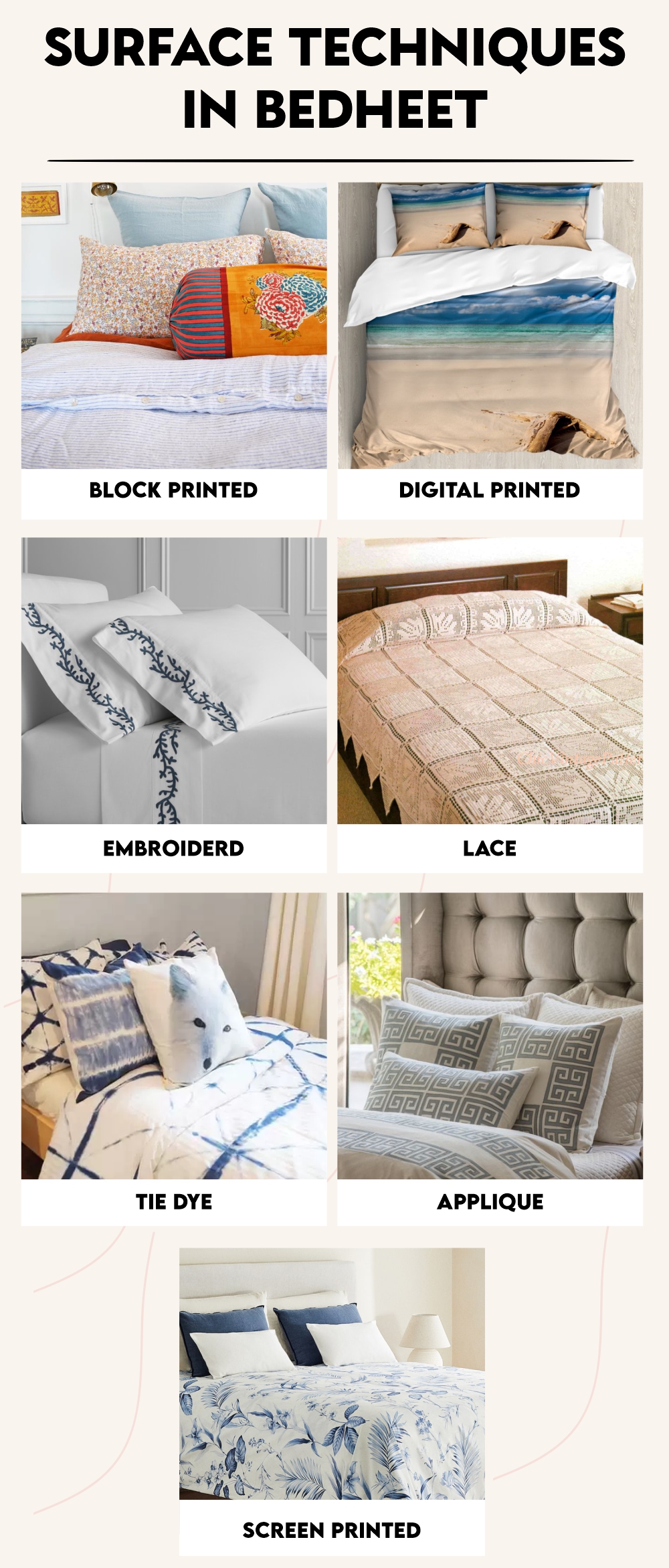

Bed Sheet Printing Process

Printed Pattern Bed Cover With 2 Pillow Covers 2200 1499.

Bed sheet printing process. The 100 pieces are soaked in the mix for 24 hours. Blue White Printed Bed Sheet With 2 Pillow Covers 2200 1499. A nozzle with liquid material can be drawn over an absorbent surface to wick out material.

This process works by material being melted and extruded through a nozzle to 3D print a cross section of an object each layer at a time. Thin layers of powder are deposited one at a time into a heated powder bed where a guided heat source solidifies it into the shape of the desired 3D model. Platen printing is typically used for short runs such as invitations name cards and stationary.

It can be used to make one or more identical images or to create repeating patterns on papers and textiles. This process is continued for 3 days. Then the cloth becomes very soft and ready to absorb colour.

Some FDM 3D printers have two or more print heads to print in multiple colours and use support for overhanging. Custom bed sheets are tailored in any length width and even depth you chooseWe can even make custom sheets for round mattresses. Custom Length and Width.

Zhou and Lu 2011. Letterpress is a relief printing process. Available in many sizes to fit all kinds of 3D Printers simply add the Magnetic Base on top of the existing print bed and the FlexPlate with attached BuildTak sheet will magnetically connect.

Describe the process of launching the business. With our cutting edge technology we can print on any quality of fabrics. Layer thickness determines the quality of the 3D print.