Advantages Of Sludge Drying Beds

It can produce valuable gas and solid.

Advantages of sludge drying beds. A disadvantage is that the dust content of the exhaust gases is. Sludge volume reduction by digestion is perhaps the most critical step in a sludge treatment and disposal scheme and inadequacies in the digestion step can result in overloading of an otherwise adequately designed sludge drying bet. Advantages of artificial media drying beds include 1 no clogging of the media 2 constant and rapid drainage 3 higher throughput rate than with sand beds 4 easy bed maintenance and 5 difficult-to-dewater sludges such as aerobically digested waste activated sludge can be dried.

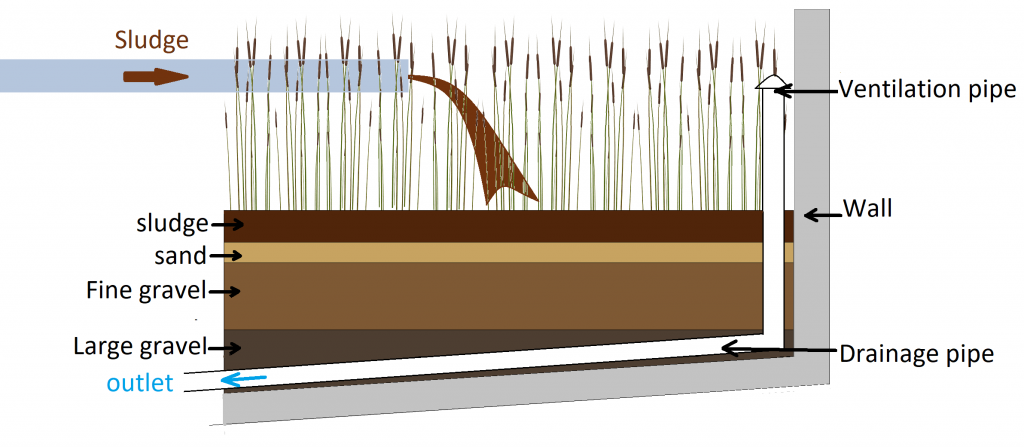

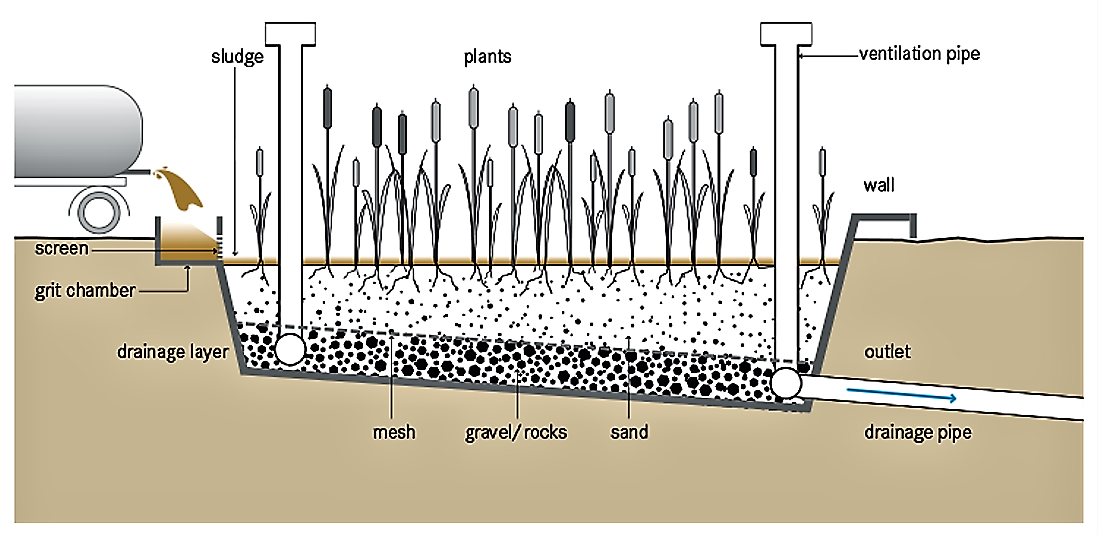

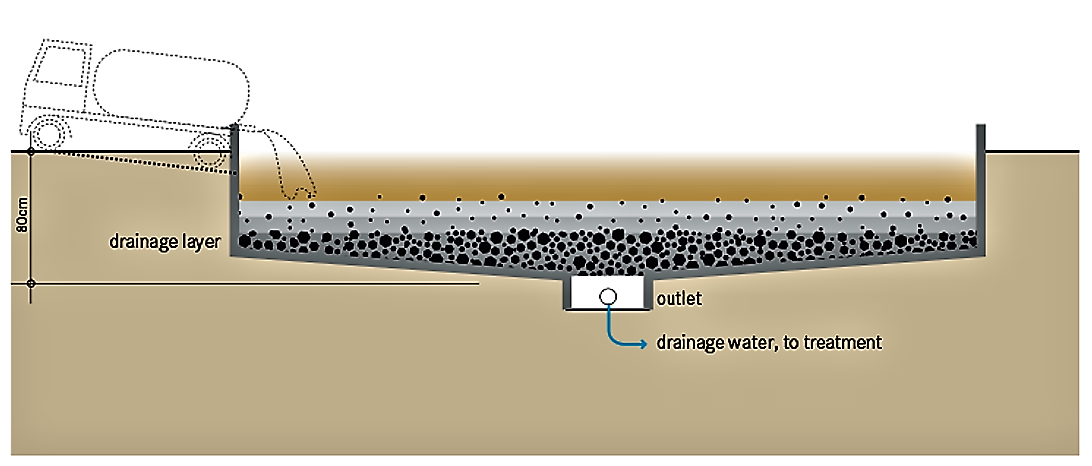

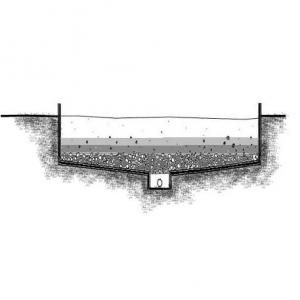

The sludge dried by the sludge dryer contains high. The water is then allowed to drain through the bed and into a network of embedded drainage pipes to allow it to be collected. Sludges of different origins and characteristics exhibit different behaviours when drying.

The sewage sludge from the digestion tank is brought and spread over the top of the. As a result filtrate quality and sludge mineralization are significantly improved compared to a simple drying bed. Sludge drying involves natural ways of drying to mechanical ways of removing water content.

Following are the advantages of active sludge process. The wedge-shaped paddle of the sludge dryer has the self-cleaning ability and can maintain the efficient heat transfer function. The beds are filled with gravel and coarse sand as a filter.

The drying process in a drying bed is based on drainage of liquid through the sand and gravel to the bottom of the bed and evaporation of water from the surface of the sludge to the air. When land is readily available normally this is the lowest capital cost. D Greater flexibility of operation permitting control on the quality of effluent is possible.

Sludge treatment wetlands also known as sludge drying reed beds are rather new sludge treatment systems based on constructed wetlands. Process Description In the most general terms drying is the use of heat to evaporate water from wastewater residual solids. Thermal drying typically must be preceded by or done in conjunction with a dewatering process and drying is usually the last process dried material can be used for a variety of purposes.